DEF Rubber Co.,Ltd.

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.

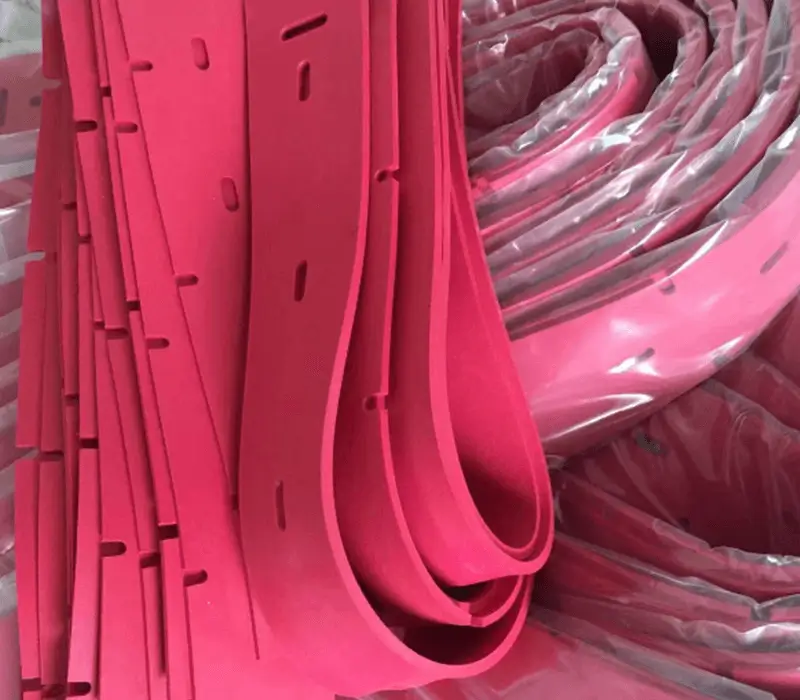

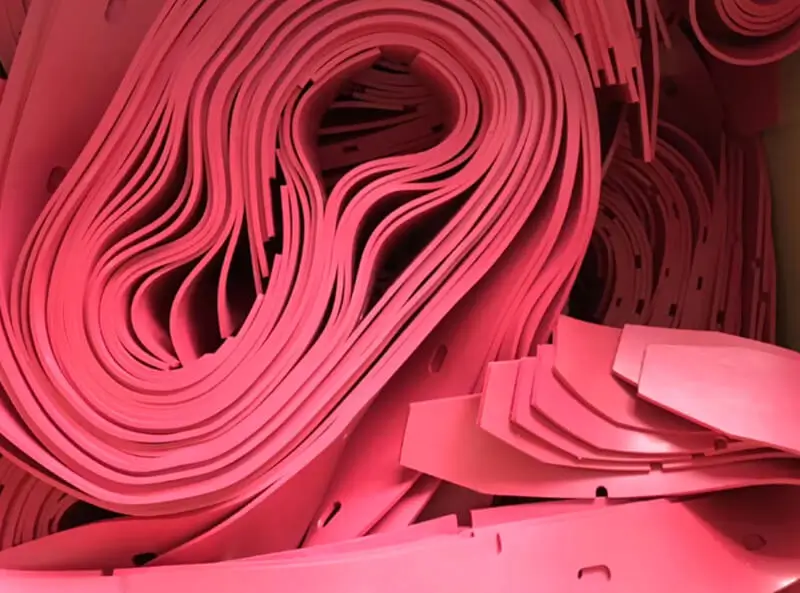

High-quality, wear-resistant rubber liners for pinch valves significantly enhance durability and efficiency.

What is a Wear-Resistant Pinch Valve?

A pinch valve controls fluid flow by compressing an internal flexible tube. It typically consists of a metal shell and an internal rubber tube, which is compressed or released by applying external pressure (mechanical or pneumatic) to control flow.

Wear-resistant pinch valves usually comprise an upper clamp, valve body, rubber liner, and lower clamp.

Common Issues with Pinch Valves:

- Rubber Tube Wear: Frequent operation causes wear and tear, requiring regular inspections and replacements.

- Clogging: The rubber tube can clog when handling fluids with particles or viscous substances.

- Pressure Loss: Significant pressure loss can occur in high-pressure applications.

- High Operating Force: Mechanical pinch valves require substantial force to operate, especially under high pressure.

Why DEF Rubber is the Best Material for Pinch Valve Liners?

- Superior Wear Resistance: Unique formulation and process, offering over three times the wear resistance of ordinary natural rubber, ideal for fluids with solid particles.

- Excellent Corrosion Resistance: Stable molecular structure resists many chemicals, enhancing valve lifespan without additional protection.

- Great Flexibility: Maintains the long-chain molecular structure of natural rubber, providing excellent elasticity and flexibility, ensuring effective flow control without cracking.

- Excellent Sealing Performance: Bonded rubber protrusions at the flange ensure long-term sealing without cracking, preventing leaks.

- Low Maintenance Costs: DEF Rubber lasts over three times longer than ordinary natural rubber, offering high cost-effectiveness and significantly reducing maintenance costs.

DEF employs an ultra-high molecular weight nano-curing agent, enhancing its wear resistance significantly.

During operation, the Natural Rubber Sheet may be damaged in these areas without sufficient tear strength in the material.

Greater material resilience ensures faster restoration, maintaining high airtightness in assembly parts.

Oily environments, traditional rubber can expand and deform, so consider using Oil-Resistant Rubber Sheets.

More Information About Rubber Lined Pinch Valve

You may still have many questions about Pinch Valve. Continue to check the FAQs about it.