DEF Rubber Co.,Ltd.

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.

Explore how rubber lining can significantly enhance the performance and longevity of Hydrocyclones, providing valuable insights for manufacturers and users alike.

What is a Hydrocyclone?

A Hydrocyclone is a device that uses centrifugal force to separate particles in a liquid suspension based on their density. It is widely used in industrial processes, such as mining, where it is employed to separate ores and remove solid particles from liquid streams, chemical plants for liquid-solid separation, and wastewater treatment facilities to remove suspended solids.

Structure and Key Components of a Hydrocyclone

- Cylindrical Section: Located at the top of the Hydrocyclone, it houses the inlet where the slurry enters.

- Conical Section: Positioned below the cylindrical section, this is the primary area where separation occurs.

- Overflow Outlet: Located at the top, this outlet is where the separated liquid and lighter particles exit.

- Underflow Outlet: Positioned at the bottom, it allows the denser solid particles to be discharged.

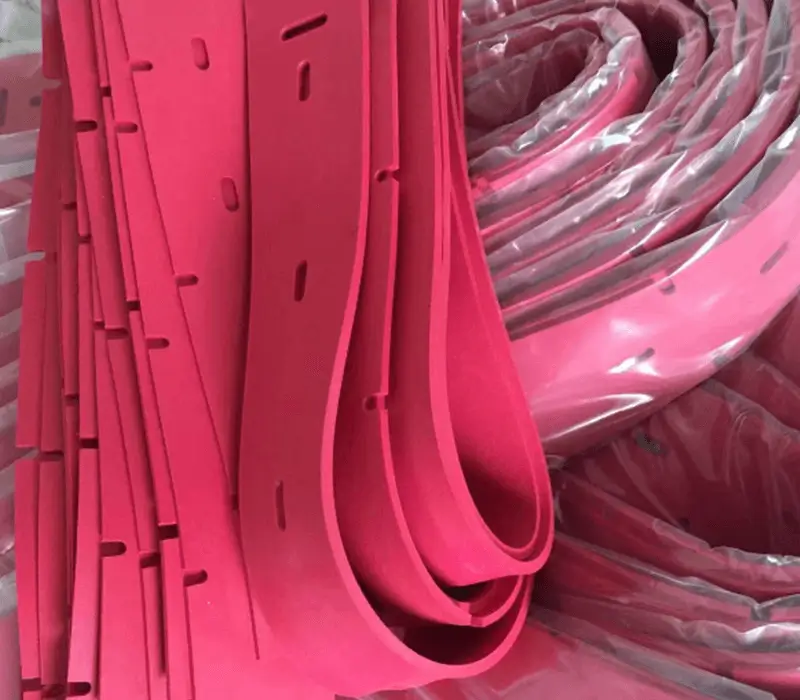

- Wear-Resistant Rubber Lining: Applied to the interior of the Hydrocyclone, this lining protects against wear and corrosion, significantly extending the device’s lifespan. DEF Rubber’s nano-engineered natural rubber is a preferred material for this purpose.

How Does a Hydrocyclone Work?

A Hydrocyclone operates by introducing a slurry tangentially into the cylindrical section at high speed. The resulting centrifugal force pushes the denser particles to the outer walls, causing them to move downward along the cone and exit through the underflow outlet. Meanwhile, the lighter particles and liquid move towards the center and are discharged through the overflow outlet at the top.

Key Features of Hydrocyclone Operation

- Simple Design: The Hydrocyclone’s structure is straightforward, with no moving parts, making it compact and easy to maintain.

- High Processing Efficiency: Despite its small size, the Hydrocyclone is capable of processing large volumes efficiently.

- Low Energy Consumption: With no mechanical parts, energy requirements are low, needing only a slurry pump to generate sufficient flow.

- Wide Applicability: Capable of handling a variety of slurry types and concentrations, with adjustable parameters to fine-tune separation efficiency.

- Low Maintenance Costs: The absence of moving parts and a simple design make maintenance easy and cost-effective.

- Longevity: The service life of a Hydrocyclone largely depends on the quality of its internal wear-resistant lining, making DEF Rubber’s products an ideal choice.

Advantages of DEF Rubber Lining

DEF Rubber is a leading provider of ultra-wear-resistant rubber materials. Their proprietary nano-engineered liquid-phase natural rubber outperforms standard materials, offering three times the lifespan of competing products. With tensile strength exceeding 24.2 MPa and tear resistance above 42 N/mm, DEF Rubber surpasses even the industry’s leading “Linatex Rubber” in key performance metrics, all while being more cost-effective, making it the ideal lining material for Hydrocyclones.

DEF employs an ultra-high molecular weight nano-curing agent, enhancing its wear resistance significantly.

During operation, the Natural Rubber Sheet may be damaged in these areas without sufficient tear strength in the material.

Greater material resilience ensures faster restoration, maintaining high airtightness in assembly parts.

Oily environments, traditional rubber can expand and deform, so consider using Oil-Resistant Rubber Sheets.

More Information About Rubber Lining for Hydrocyclone

You may still have many questions about Rubber Lining for Hydrocyclone. Continue to check the FAQs about it.