고무 라이닝 절차-금속 대 고무 접합 공정

리나텍스(Lina-tex) 유형 고무 소재의 고무 라이닝 공정에 대한 상세한 설명으로, 금속과 고무의 접착 공정 단계 및 기술적 핵심 사항을 포함합니다.

금속 표면 준비 공정:

1단계. 연삭 및 거칠게 하기:

금속 표면을 갈거나, 그릿 블라스트하거나, 거칠게 만들어 표면 프로필을 80마이크론으로 만듭니다. 그 후, 금속 표면을 철저히 청소하여 오염 물질을 제거합니다.

2단계. 표면 전처리:

폭파 후 4시간 이내에 금속 전처리제(예: 로타이트 SF-7467)을 세척하고 건조한 금속 표면에 바릅니다. 이 전처리는 더 나은 접착력을 보장합니다.

3단계. 전처리제 제거:

전처리제를 1분간 도포한 후(5분을 초과하지 마십시오) 흡수성 폼 롤러와 흡수성 종이를 사용하여 잉여분을 제거하십시오. 이 처리로 최대 7일 동안 금속 표면을 녹으로부터 보호할 수 있습니다.

4단계. LPT1205 금속 접착제 적용:

완전히 섞는다 LPT1205 금속 접착제 적용 전. 브러시나 롤러를 사용하여 준비된 금속 표면에 균일한 층을 적용합니다. 적용 후 접착제를 실온에서 60분 동안 자연 건조시킵니다. 가능하면 열을 가하면 접착 성능이 향상됩니다. 일반적인 건조 필름 두께는 5.1~10.2마이크론 사이여야 합니다. 접착제를 적용한 후 금속 부품을 적절히 보관하고 먼지, 오일 및 습기로부터 보호하며 최대 보관 기간은 1개월을 초과하지 않아야 합니다.

LPT1205의 작동 지침과 안전 가이드라인에 대해 자세히 알아보려면 클릭하여 다운로드하세요. LPT1205 MSDS, LPT1205 TDS.

대체 제품:

고객은 CHEMLOK 205 및 CHEMLOK 220 제품도 사용할 수 있습니다. 먼저, 처리된 금속 표면에 CHEMLOK 205 층을 도포합니다. 완전히 건조되면 CHEMLOK 220의 두 번째 층을 도포합니다.

메모:

가황이 필요한 경우 접착제를 도포한 후 처리된 금속 작업물을 뜨거운 금형에 넣습니다. 고무로 빠르게 채우고 금형을 닫아 금속 접착제의 조기 경화를 방지합니다. 조기 경화로 인해 고장이 발생할 수 있습니다. 금속 접착제와 고무가 동시에 경화되도록 합니다. 경화 시간은 최상의 접합 성능을 달성하기 위해 가황 시간과 일치해야 합니다.

고무 표면 준비 공정:

1단계. 연마:

텅스텐 카바이드 연삭 휠을 사용하여 오염되지 않은 고무 접합 표면을 거칠게 합니다. 연삭하는 동안 고무를 닦거나 태우지 않도록 주의하세요. 연삭 후 고무 표면을 철저히 청소하세요. 고무가 공장에서 단면 거칠게 처리된 경우 추가 처리가 필요하지 않습니다.

2단계. 세척 및 건조:

고무 표면을 청소하십시오 LPT360 세척제 먼지와 잔여물을 제거합니다. 세척 후 표면을 자연 건조시키거나 열을 가해 완전히 건조시키고 고무에 습기가 없는지 확인합니다.

3단계. 고무를 자르다:

고무를 필요한 모양과 크기로 표시하고 잘라냅니다.

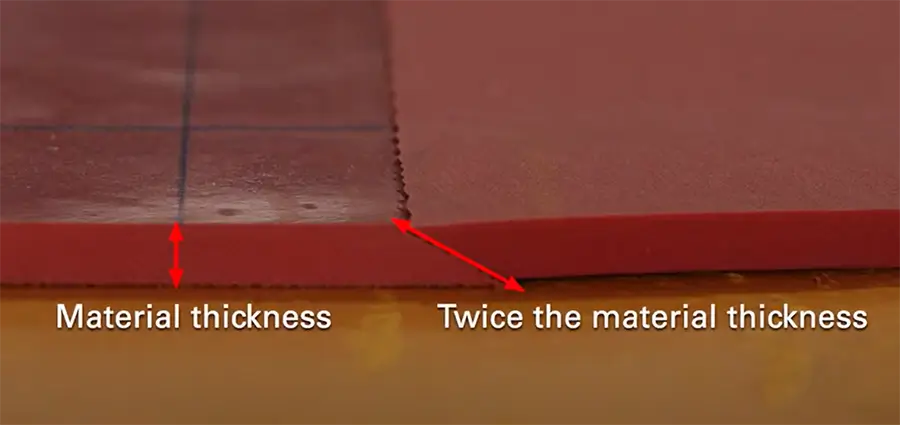

관절 치료:

일반적으로 표준 사다리꼴 랩 조인트가 사용되며 조인트에서 경사로 겹치는 길이가 고무 두께의 최소 2배가 되도록 합니다.

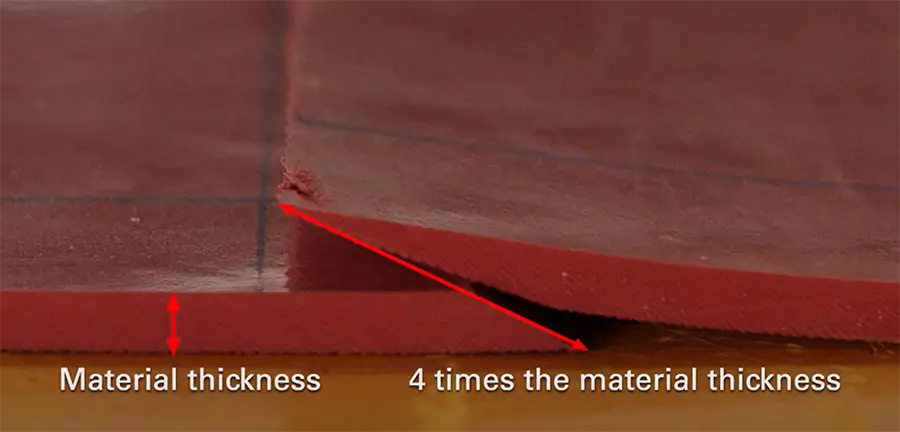

물탱크 라이닝과 같이 산성 또는 부식성이 강한 환경에서는 겹쳐지는 사다리꼴 모양의 조인트를 사용해야 하며, 경사면이 겹쳐지는 길이는 고무 두께의 4배가 되어야 합니다.

4단계. 고무 처리제 적용:

붓다 LPT366 고무처리제 B성분 에 구성 요소 그리고 B가 완전히 녹을 때까지 철저히 섞습니다. 참고: 혼합 처리제는 4시간 이내에 사용해야 합니다.

혼합 후, 준비된 고무 접합 표면에 고무 처리제를 균일하게 도포합니다. 자연 건조시키거나 열을 가해 건조 과정을 가속화합니다.

LPT 366의 작동 지침과 안전 가이드라인에 대해 자세히 알아보려면 클릭하여 다운로드하세요. LPT 366 MSDS ,LPT 366 TDS .

금속-고무 접합 공정:

1단계. 접착제 혼합:

혼합 LPT3008 접착제 그리고 ER65 경화제 100:5의 무게 비율로. 혼합물이 완전히 섞였는지 확인하세요.

메모: 혼합된 접착제는 3시간 이내에 사용해야 합니다. 3.5kg 드럼당 LPT3008 접착제 약 4제곱미터의 고무를 덮습니다.

2단계. 고무 및 금속 표면에 접착제 적용:

접착제를 두 겹으로 도포하고 각 겹이 고르게 펴져 접착제가 접합 표면에 완전히 침투되도록 합니다. 첫 번째 겹을 도포한 후 두 번째 겹을 도포하기 전에 완전히 말리십시오. 이 작업은 하루나 이틀에 걸쳐 수행할 수 있습니다.

LPT 3008의 작동 지침과 안전 가이드라인에 대해 자세히 알아보려면 클릭하여 다운로드하세요. LPT 3008 MSDS, LPT 3008 TDS, ER 65 물질안전보건자료.

3단계. 본딩:

두 번째 코팅이 만져도 마르고 더 이상 끈적거리지 않으면 본딩 프로세스를 시작합니다. 두 본딩 표면을 정렬하고 함께 누릅니다. 고무 망치를 사용하여 중앙에서 바깥쪽으로 두드려 표면이 단단히 본딩되고 공기 주머니가 제거되었는지 확인합니다.

4단계. 본딩 후:

본딩을 완료한 후 고무에 대한 절단 또는 연삭 작업을 진행하기 전에 최소 3시간을 기다리십시오. 본딩된 재료가 최소 24시간 동안 쉬게 하여 충분한 본딩 강도를 확보하십시오.