Natural Rubber Sheet

DEF Rubber: Your Premier Factory, Manufacturer, Supplier, and Exporter of High-Quality Natural Rubber Sheet. Contact us for free samples.

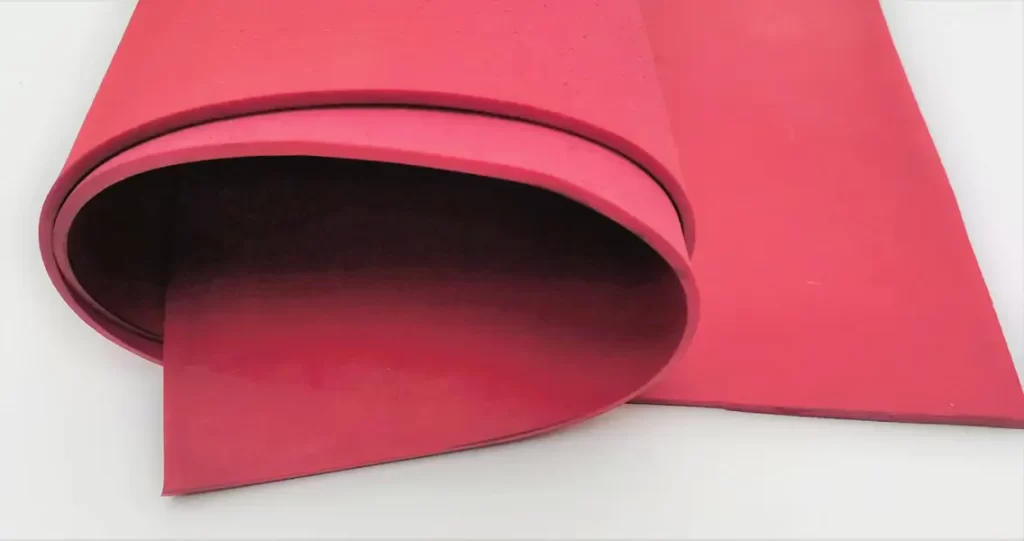

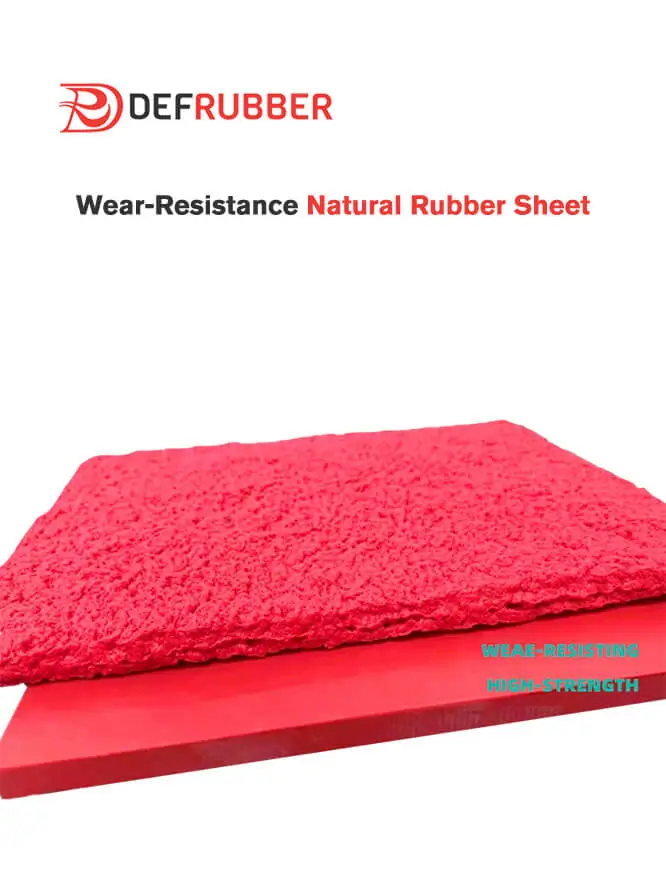

Defining Natural Rubber Sheets.

Natural rubber (NR) refers to natural latex collected from rubber trees, processed through procedures such as coagulation and drying to produce elastic solid material (raw rubber). Its primary chemical component is rubber hydrocarbon, typically comprising over 90%, with the remaining components including proteins, fatty acids, sugars, and other organic substances. The microstructure of natural rubber mainly consists of large molecular chain-like structures, with a wide range of molecular weights, but the majority have molecular weights around thirty thousand, resulting in high strength, reaching up to three megapascals. DEF Rubber uses high-quality natural rubber latex as raw material, incorporates other additives based on a formulation, and through a specialized wet rubber refining process, produces wear-resistant natural rubber sheets with a natural rubber content exceeding 95%. Thanks to improved process design, it preserves the unique long molecular chain structure of natural rubber, retaining its high strength and exceptional wear resistance, making it the best choice for wear-resistant rubber products under wet grinding conditions. Since its introduction to the market, it has earned customers’ trust due to its superior quality compared to peers and highly competitive pricing. It finds extensive use as wear-resistant linings in various industrial equipment, such as pump impellers, hydrocyclones, screen plates, and liners for screening equipment, conveying pipes and bends, valves and sealing components, slurry pumps, sludge pumps, and more. Additionally, it is used in products like floor scrubber squeegees and rubber timing belts. If you are interested in DEF Rubber’s wear-resistant natural rubber sheets, floor scrubber squeegees, wear-resistant rubber linings, or other products, please feel free to contact us.

Quick Q&A-About Natural Rubber Sheet.

Regarding ‘Natural Rubber Sheet,’ the questions people may concern themselves with and their answers usually involve the following aspects:

Our sole pursuit is to deliver excellent products and serve our customers.

We will continuously innovate, grow together with our customers, and be your best partner.

Technology Sharing

DEF Rubber Co.,Ltd.

Get in touch with us today!

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.