Is There a Complete Replacement for LX-Type Rubber on the Market?

Gain insights into the characteristics of LX-type rubber, analyze alternative products available on the market, and evaluate the potential for replacing LX-type rubber in various applications.

What Is LX-Type Rubber?

If you’re not familiar with LX-type rubber, click the article below to learn more about this unique material.

Is LX-Type Rubber Replaceable?

LX-type rubber is widely appreciated in the industrial sector for its exceptional wear resistance, elasticity, and tear resistance. However, with market evolution and diversified user demands, finding equivalents to LX-type rubber that offer comparable quality but more cost-effective and varied options is increasingly important. Are there perfect substitutes for LX-type rubber on the market? This article explores the characteristics and advantages of these alternatives to help customers make more comprehensive and economical decisions.

Core Characteristics of LX-Type Rubber

LX-type rubber is renowned for its superior physical properties, especially in wear resistance, elasticity, and tear resistance. These traits make it a preferred choice in industries like mining, cleaning, and manufacturing. However, it is not an exclusive product, as the market now offers materials that match or even exceed its performance. The high cost and limited supply of LX-type rubber materials may constrain industrial development in some cases.

Market Overview of LX-Type Rubber Substitutes

The market is filled with various rubber types, and many attempts have been made to replace LX-type rubber with other materials. Each type of rubber has its application domain, but LX-type rubber remains a recognized standard for wet grinding conditions. However, it is not only one company that produces this rubber. DEF Rubber manufactures LX-type rubber-like products, customizable in color and size to client needs, and has gained widespread acceptance for its quality. With its excellent value for money and customer service, DEF Rubber is an alternative worth considering.

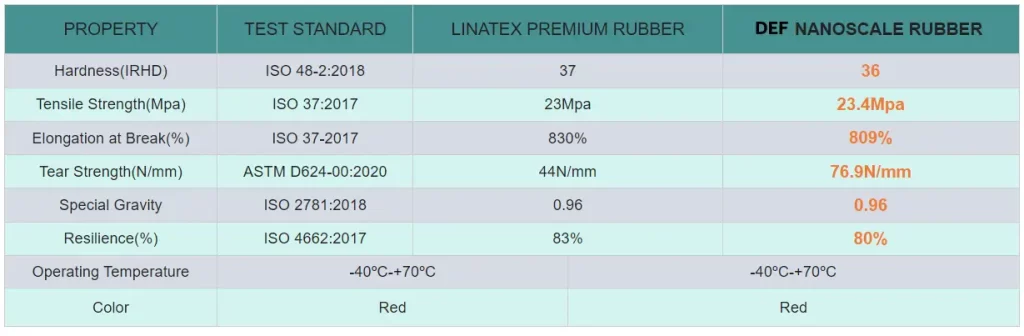

Comparison of Physical Performance Parameters Between LX-Type Rubber and Its Alternatives

Using industry-standard testing protocols, we conducted a laboratory analysis comparing the core performance indicators of LX-type rubber with those of its alternative, represented by DEF Rubber. The results, summarized in the table below, indicate that DEF Rubber matches LX-type rubber in all key performance metrics and even surpasses it in certain areas.

These findings demonstrate that high-quality alternatives to LX-type rubber, such as DEF Rubber, are now fully capable of meeting the rigorous quality demands of customers.

Experimental results indicate that DEF high-quality natural rubber exhibits the least amount of wear, followed by polyurethane materials, with standard natural rubber performing the poorest.

Importance of Cost-Effectiveness

In the selection of industrial materials, cost-effectiveness remains a core consideration. Materials offering high value for money can reduce long-term operational costs while maintaining performance. However, pursuing cost-effectiveness doesn’t mean compromising quality standards. Opting for lower prices might lead to higher maintenance costs or even severe safety incidents. Therefore, when pursuing cost-effectiveness, we should consider factors beyond quality, such as brand premiums and supply chain costs.

Diversity and Customization Advantages of LX-Type Rubber Substitutes

Providing a range of customized solutions is key to meeting diverse industrial needs. Unlike LX-type rubber, market substitutes offer more customization, a broader range of colors and sizes, and subsequent cutting and processing services. These tailored solutions can provide optimal matches for specific applications, better meeting customer needs and cost-effectiveness.

Case Study of LX-Type Rubber Substitute

In China, a mining company replaced LX-Type Rubber with high-quality wear-resistant rubber products from DEF Rubber, which matched the quality of LX-Type and reduced material costs by over 50%, while maintaining efficiency.

Conclusion

In conclusion, several products on the market can replace LX-type rubber, offering perfect substitutions in specific industrial applications. These materials not only match LX-type rubber in quality but also provide better options in terms of value for money and diversity. They offer additional advantages in long-term cost-effectiveness, environmental impact, and customization. With ongoing advancements in material science, more innovative substitutes will emerge, enriching industrial material choices and propelling development across various sectors.

Disclaimer

This article uses the term ‘LX-Type Rubber’ for clarity. We are not affiliated with, endorsed by, or authorized by any specific brand. All trademarks mentioned in this article are the property of their respective owners. This article is for informational purposes only and does not imply any partnership, sponsorship, or endorsement.