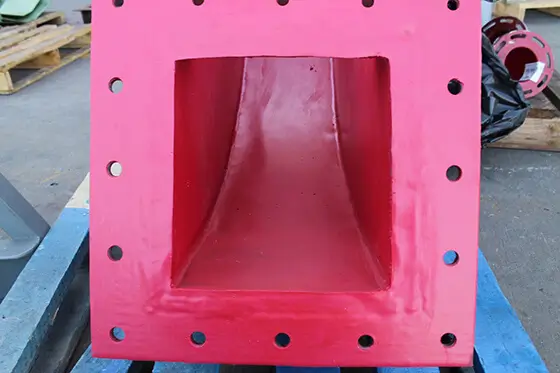

Rubber Liner

High quality Rubber Liner.

We are Experts in High-Quality Custom Moulded Rubber Linings.

We can customize Rubber Liners in various shapes and designs.

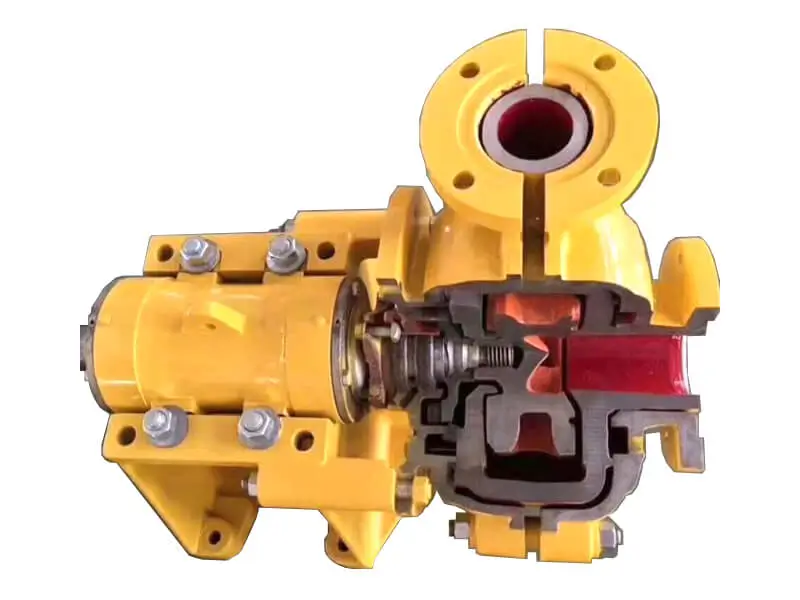

We understand that applying a layer of Rubber Lining to equipment contact surfaces effectively extends the equipment’s lifespan. A common method involves cutting Natural Rubber Sheets into appropriate shapes and bonding them to the contact surfaces using specialized adhesive. This approach is cost-effective, especially for non-mass-produced equipment, as it eliminates the need for molds. However, when dealing with complex-shaped and mass-produced equipment such as Slurry pumps, we require a more reliable and cost-effective solution. In such cases, using Rubber Liner mouldings is undoubtedly the best choice.

When should Rubber Liner mouldings be used?

Equipment manufactured in batch production

If our Rubber Lining is intended for equipment manufactured through batch production, continuing to use the traditional method of adhering Natural Rubber Sheets would undoubtedly significantly reduce our efficiency. In this case, opting for Rubber Liner moldings is a better choice.

Equipment with complex shapes

Sometimes, for equipment with complex shapes, it’s not feasible to manually apply a Natural Rubber Sheet to its surface. Using Rubber Liner moldings is a viable solution, even though it may increase our costs. Considering the safety and reliability it provides, it’s all worthwhile.

Equipment with high protection requirements

Sometimes, in applications where we demand high levels of protection for our equipment, requiring excellent sealing, a perfect fit to the equipment’s surface, extended lifespan, and impeccable aesthetics, a precision-crafted Rubber Liner molding is the solution to meet your demand for higher-quality protection.

If you’re still uncertain?

If you’re unsure about the best protection solution for your equipment, please contact us directly. Our experienced engineers will recommend the most suitable and cost-effective option based on your product’s shape, quantity, and working environment.

The best partnerships often begin with your courageous attempts.

It is widely used in pumps, flat bottom classifiers, hydrocyclones, flotation cells, screens, and more.

Technology and case sharing

DEF Rubber Co.,Ltd.

Get in touch with us today!

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.