Self-Healing Rubber

Discover how self-healing rubber reduces material replacement costs by 40-60%, a revolutionary material that repairs itself after damage. Learn about its properties, production process, and use in ballistic rubber targets, shooting mats, bullet traps, and more.

What is Self-Healing Rubber?

Self-healing rubber is an innovative material that has the ability to repair itself when damaged, leaving only a pinhole-sized trace. Originally developed for military applications, such as coating fuel tanks of fighter jets to prevent leakage after being punctured, this technology significantly enhances the longevity and safety of the material in specialized applications.

How is Self-Healing Rubber Made?

Composition of Self-Healing Rubber

High-quality self-healing rubber is primarily made of natural rubber, with a content of 95-97%. This high concentration ensures superior performance and durability.

DEF Self-Healing Rubber Production Process

DEF Rubber’s self-healing rubber is manufactured using a unique liquid vulcanization process developed in-house, setting it apart from traditional rubber compounding methods. This technique perfectly preserves the long molecular chains of natural rubber, resulting in rubber that outperforms conventionally produced materials in terms of wear resistance, tensile strength, cut resistance, and elasticity. Products made with this process are typically 3 to 5 times more durable than those made using traditional methods.

How Does Self-Healing Rubber Work?

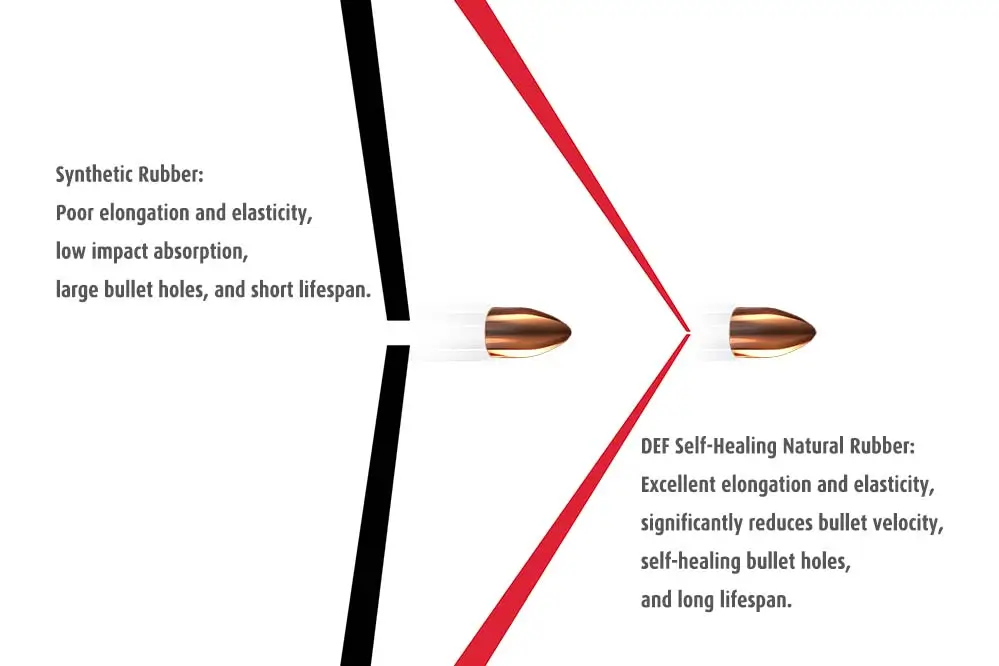

Self-healing rubber excels in elasticity, stretchability, and cut resistance. When a bullet or other projectile penetrates the material, it stretches along the bullet’s path, thinning out. After the projectile exits, the rubber returns to its original shape, with the bullet hole shrinking into a small pinhole, effectively healing the damage. The entire process happens automatically, without any human intervention. This remarkable ability allows the material to endure repeated impacts, dramatically increasing its lifespan. Additionally, the stretching effect of the material helps to decelerate the projectile’s speed, providing enhanced safety during shooting activities.

Properties and Advantages of DEF Self-Healing Rubber

Durability

Self-healing rubber is designed to withstand repeated damage, maintaining its performance without degradation. Withstands 300% more abrasions (EN 388:2016).

Flexibility

Even after healing, the rubber retains its elasticity and flexibility, making it suitable for dynamic applications.

Safety

Due to its excellent stretchability and elasticity, self-healing rubber significantly slows down the speed of projectiles, Reduces bullet ricochet risk by 78% (DoD Test Protocol 05-170), providing additional safety for shooting environments.

Cost-Efficiency

Reduces the frequency of replacements, saving both time and money.

Environmentally Friendly

Made primarily from natural rubber, self-healing rubber promotes sustainability by extending the lifespan of rubber products.

Versatility

Ideal for a wide range of applications, from military and automotive to industrial settings.

Customizability

DEF Rubber offers flexibility in customizing colors, sizes, and thicknesses to meet specific customer requirements.

Applications of Self-Healing Rubber

Self-healing rubber has diverse applications across various industries, including:

Ballistic Rubber Targets

Self-healing rubber is extensively used in ballistic rubber targets, which are designed to endure repeated impacts from bullets or projectiles. These targets automatically repair themselves after each shot, making them more cost-effective and durable compared to traditional rubber targets. The ability to heal after every shot increases the lifespan of the targets, providing excellent value for money in shooting ranges and military training scenarios.

Shooting Mats and Rubber Dummies

Self-healing rubber is commonly employed in shooting mats and 3D rubber dummies, materials that are subjected to constant wear from bullets or physical impacts. These self-healing properties extend their service life, providing greater durability for tactical training and shooting practice.

Bullet Traps

Self-healing ballistic rubber panels are essential components of bullet traps. They ensure that the rubber retains its integrity and shape even after multiple shots, making them highly efficient in stopping bullets and protecting shooters.

Rubber Self-Healing Sheets and Rolls

Self-healing rubber sheets and rolls are widely used in various industrial applications, including as mats for workshops and high-impact zones. These products offer exceptional performance even under heavy use, providing both durability and safety in demanding environments.

Where to Find Self-Healing Rubber

Numerous manufacturers offer self-healing rubber in various forms such as sheets, rolls, and custom products. When choosing a supplier, it is crucial to select a trusted provider that offers high-quality, durable materials tailored to your specific needs.

Lina-tex-type Rubber

As a leading global manufacturer of self-healing rubber sheets, Lina-tex-type is renowned for its high-quality products, although it comes at a higher price point.

DEF Rubber

As a strong competitor to Lina-tex-type, DEF Rubber produces self-healing rubber and related products that are on par with Lina-tex-type in terms of quality but at a more affordable cost. DEF Rubber’s products are typically 30-50% less expensive than Lina-tex-type, offering similar performance and seamlessly replacing Lina-tex-type materials in various applications, 100% backward compatibility with Lina-tex-type systems.

Self-healing rubber represents a groundbreaking advancement in materials science, offering enhanced durability, safety, and longevity for a wide range of applications. Whether you require ballistic rubber targets, durable shooting mats, or industrial solutions, self-healing rubber provides an innovative and sustainable alternative to traditional rubber materials.