Essential Materials and Leading Suppliers for Squeegee Blade Production

Explore the common materials and properties used in manufacturing Squeegee blades, and how to select Squeegee blade materials suppliers.

What is a Squeegee Blade?

A squeegee blade is a generic term for a product typically made from rubber or synthetic materials. It is used to clean flat surfaces by scraping off liquids and dirt.

Typical Applications of Squeegee Blades – Floor Scrubber Squeegee Blades

Squeegee blades are commonly used in various contexts, such as hand-held squeegees for cleaning windows and cars in everyday life, large squeegee strips in floor scrubbers for malls or factories, and in the printing industry to spread ink over screens.

Taking the typical floor scrubber squeegee blade as an example, a common floor scrubber setup is as follows: at its front end, it has a circular brush that cleans the floor. As the brush rotates, it applies detergent and water to lift dirt from the floor, forming wastewater, which is then scraped off and fully absorbed by a water suction device at the rear of the machine. Thus, the performance of the floor scrubber squeegee blade will determine its cleaning effectiveness.

Click “Floor Scrubber Squeegee” to learn more.

What Materials Are Squeegee Blades Made Of?

The most commonly used raw materials for manufacturing squeegee blades are rubber types that vary depending on the application context, such as ordinary rubber, natural high-abrasion-resistant rubber, polyurethane rubber, and neoprene. Besides rubber, other synthetic materials like silicone rubber and plastics are also used to manufacture squeegee blades.

Material Performance Requirements for Squeegee Blades

For different usage scenarios in daily or industrial contexts, squeegee blades have various performance requirements, including:

- Abrasion Resistance: This almost determines the lifespan of a squeegee blade, especially when used on rough or hard surfaces.

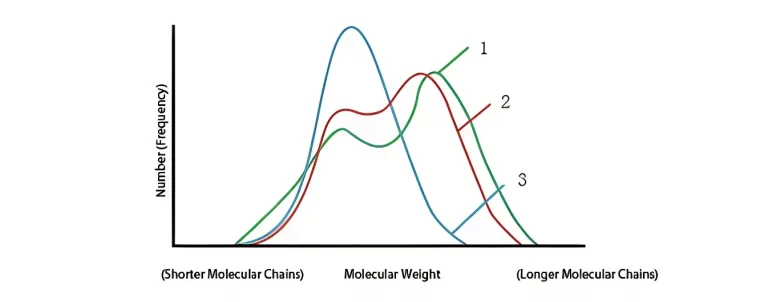

- Flexibility: Appropriate flexibility and elasticity are key to ensuring effective cleaning; materials that are too hard or too soft can impair the scraping effect.

- Tear Resistance: Since squeegee blades are often torn or punctured during use, materials with good tear resistance can extend their life.

- Chemical Resistance: When cleaning special liquids, including greases, solvents, inks, detergents, or other chemicals, good chemical resistance prevents the squeegee blade from corroding.

- Temperature Resistance: In extreme application environments, such as high or low temperatures, materials with good temperature resistance ensure effective cleaning.

- UV Resistance: For squeegee blades used outdoors over long periods, good UV resistance prevents them from aging and losing elasticity quickly.

Common Raw Materials for Squeegee Blade Manufacturing and Their Features

- Natural High Abrasion-Resistant Rubber: A high-end material for squeegee blades, recognized as the best rubber material under wet grinding conditions for its abrasion resistance and flexibility, though it has average chemical resistance.

- Polyurethane Rubber: Known for good abrasion and chemical resistance, commonly used in oil-rich environments.

- Ordinary Rubber: An economical option used in less demanding applications, replacing natural high-abrasion-resistant rubber, though with only a third of its lifespan.

- Silicone Rubber: Known for excellent flexibility and temperature resistance, suitable for applications with specific temperature requirements.

Main Suppliers of Squeegee Blade Materials

The manufacturing process for squeegee blades is relatively simple; however, the quality of the raw materials often determines the product’s quality. Thus, choosing the right supplier is crucial for manufacturing high-quality squeegee blades. Taking the most representative material, “Natural high-abrasion-resistant rubber,” as an example, we analyze how to choose the right material supplier for squeegee blades.

In producing high-quality floor scrubber squeegee blades, natural high-abrasion-resistant rubber is the preferred material. This material was first popularized by the “Weir Rubber” company in the market and has gained an excellent reputation due to its superior performance. Its “Lina-tex-type Rubber” brand has become synonymous with high-quality natural abrasion-resistant rubber.

Click to learn “What is Lina-tex-type Rubber?“

However, its high popularity also brings a significant brand premium, so more and more companies are looking for products that can completely replace “Lina-tex-type Rubber.”

We have also written an article about “Is there a complete replacement for Lina-tex-type Rubber on the market?“

How to Choose a Squeegee Blade Raw Material Manufacturer?

So, if you are a factory needing to purchase “Lina-tex-type Rubber” or similar high-quality rubber, your concerns might be:

- High Quality: The quality is market-verified.

- High Efficiency: No need for new experiments and tests.

- Temporary Purchase: You only need a small amount temporarily.

- Not Cost-Sensitive: You can afford a high brand premium due to small usage volume.

In that case, opting for “Lina-tex-type Rubber” produced by “Weir Rubber” is a good choice.

If your concerns are:

- High Quality: Although the production of this type of high-abrasion-resistant natural rubber is challenging, there are high-quality products in the market that can fully replace “Lina-tex-type Rubber.”

- Willing to Try: We are willing to test samples of similar products in the market to verify if they can completely replace “Lina-tex-type Rubber,” although this requires some upfront time and effort.

- Long-Term Purchase: The initial trial process is worthwhile if you need a long-term supply.

- Cost-Effective: If your annual purchase volume and amount are significant, choosing cost-effective products can save a lot of money.

- Maintaining Competitive Edge: As competition intensifies, having a cost-effective supply chain, consistent high-quality assurance, and continuous technological innovation can help us stand out from competitors.

Then you might consider other excellent alternatives to “Lina-tex-type Rubber” in the market. A standout alternative is “DEF Rubber,” which specializes in producing high-quality natural abrasion-resistant rubber products that perfectly replace “Lina-tex-type Rubber.” If you are interested in their products, please read: “High-Quality Natural Abrasion-Resistant Rubber Sheet.“