DEF Rubber Co.,Ltd.

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.

Explore why rubber lining significantly enhances the performance and lifespan of slurry pumps, providing valuable insights for manufacturers and users of slurry pumps.

What is a Slurry Pump?

A slurry pump is specifically designed to handle and transport fluids containing suspended solid particles. These pumps typically feature an outer shell made from robust chrome alloy steel or other metals, with an internal lining of wear-resistant and corrosion-resistant rubber. This unique structure allows the pump to withstand long-term erosion and abrasion from corrosive particles.

Main Components of a Slurry Pump:

- Impeller: The core component of a slurry pump, providing the driving force for slurry transportation.

- Pump Casing: The structural support housing the impeller, directing the slurry flow through various pathways.

- Shaft and Bearings: Supporting the impeller and transferring power from the motor to the impeller.

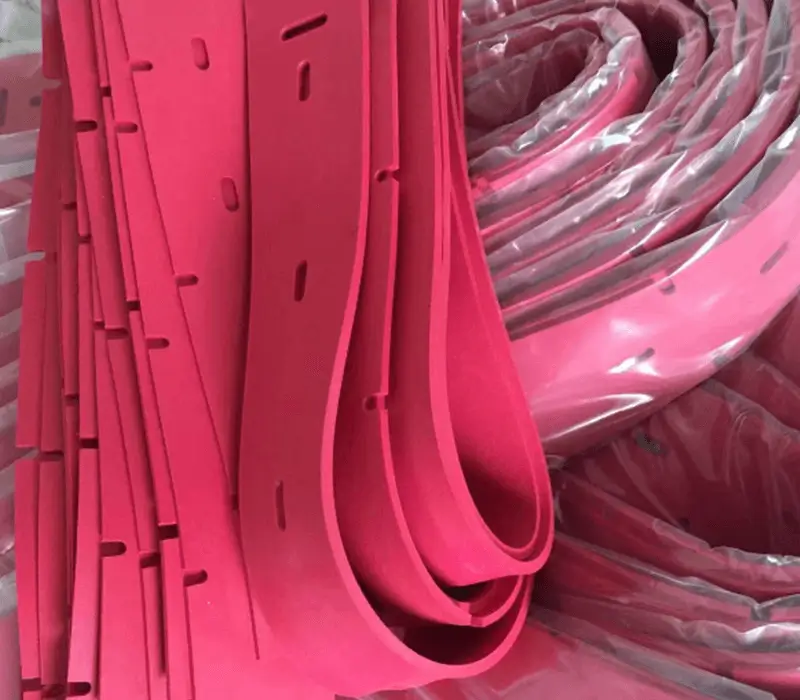

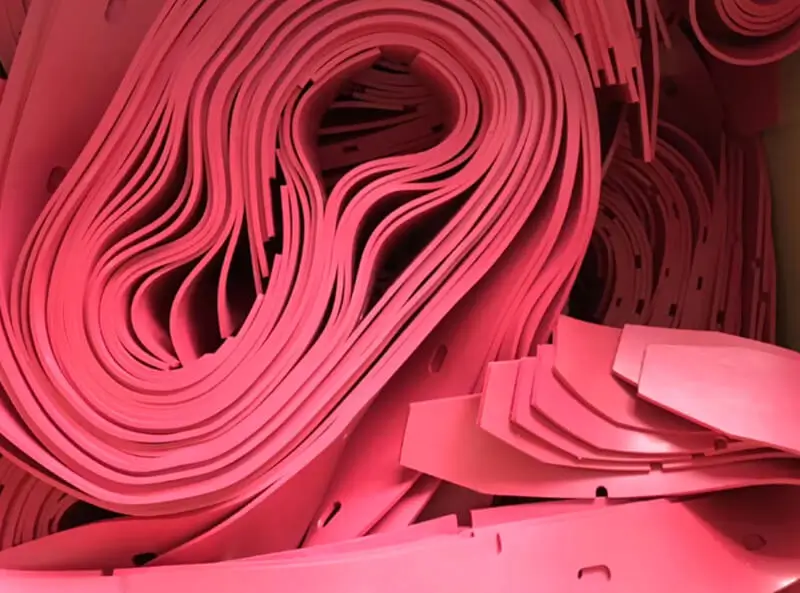

- Wear-Resistant Rubber Lining: Made from high-quality, wear-resistant rubber, typically molded to fit the pump casing perfectly. These linings offer excellent wear, corrosion resistance, and sealing performance, significantly extending the pump’s lifespan. DEF Rubber’s high-quality natural wear-resistant rubber linings are considered the best alternative to the industry-renowned “Linatex Rubber” due to their superior performance and cost-effectiveness.

- Drive System: Can be powered by electric motors, diesel engines, or other driving mechanisms.

Working Principle of a Slurry Pump:

A slurry pump operates by utilizing the centrifugal force generated by a rotating impeller to move the slurry. As the impeller spins, it accelerates the slurry towards the edge of the impeller, pushing it outwards while creating a low-pressure zone that draws more slurry in, resulting in a continuous flow of slurry.

Operational Characteristics of a Slurry Pump:

- High Durability and Wear Resistance: Designed to withstand the abrasion and corrosion caused by solid particles in the slurry, ensuring high durability and wear resistance.

- Good Sealing Performance: Ensures excellent overall sealing, especially at joints and bearings, typically employing specialized mechanical seals to prevent leaks.

- High Power Requirements: Capable of handling slurries of various particle sizes and concentrations, demanding significant power input.

Why Choose DEF Rubber Lining for Slurry Pumps?

- Superior Wear and Corrosion Resistance: Unique formulation and manufacturing process result in a wear index over 130%. Under identical conditions, the lifespan can be three times that of standard rubber, with superior tear resistance, corrosion resistance, and aging resistance.

- Excellent Sealing: Molded rubber linings fit perfectly, ensuring no leaks.

- Easy Maintenance: Long lifespan minimizes the need for frequent lining replacements, providing tear resistance and zero maintenance over long periods.

- High Efficiency: The lower density of rubber impellers and linings compared to metal counterparts boosts efficiency by over 30% with the same power input.

- Reduced Noise: Rubber’s excellent damping and sound absorption properties significantly reduce noise pollution.

- Cost-Effective: DEF Rubber offers comparable quality to Linatex Rubber at less than half the price, significantly reducing usage and maintenance costs.

- Wider Application Range: Benefiting from rubber’s superior physical and chemical properties, DEF Rubber linings are suitable for a broader range of applications than metal pumps, including the transportation of coal slurry, kaolin, and sand in mining, riverbed sludge removal, hydrocyclone feeding, and wastewater treatment.

DEF employs an ultra-high molecular weight nano-curing agent, enhancing its wear resistance significantly.

During operation, the Natural Rubber Sheet may be damaged in these areas without sufficient tear strength in the material.

Greater material resilience ensures faster restoration, maintaining high airtightness in assembly parts.

Oily environments, traditional rubber can expand and deform, so consider using Oil-Resistant Rubber Sheets.

More Information About Rubber Lining for Slurry Pump

You may still have many questions about Rubber Lining for Slurry Pump. Continue to check the FAQs about it.