Non-Marking Rubber Sheet

Learn about the non-marking, wear-resistant, cushioning, and sealing properties of non-marking rubber sheets and explore their applications in industries such as industrial, cleaning, medical, and food processing.

What is a Non-Marking Rubber Sheet?

In industrial production and applications with high demands, it is essential that rubber surfaces leave no marks. These marks could be due to the rubber being too hard, causing surface damage, or due to residue left behind from insufficient cleaning. Non-marking rubber sheets are specially designed for sensitive surfaces or demanding work environments, ensuring no damage or residue on surfaces while maintaining excellent sealing properties.

Common Materials for Non-Marking Rubber Sheets

Non-marking rubber sheets are commonly made from natural rubber, silicone, or polyurethane. Natural rubber has good wear resistance and moderate cost, but poor oil resistance. Silicone sheets can withstand high temperatures and are relatively inexpensive, but have poor abrasion resistance. Polyurethane rubber offers excellent wear and oil resistance but is more expensive.

The ultra-wear-resistant natural rubber sheets produced by DEF Rubber are also non-marking. They are soft, with a Shore hardness of 36-40, and offer wear resistance several times greater than similar products, along with excellent tear and tensile strength.

Features and Advantages of DEF Non-Marking Rubber Sheets

Superior Wear Resistance

DEF Rubber uses a unique formula and liquid-phase process to produce natural rubber sheets that retain the long-chain molecular structure of natural rubber, providing wear resistance more than three times that of standard natural rubber sheets.

High Elasticity and Cushioning

DEF Rubber retains the high elasticity of natural rubber with a balanced hardness, making it neither too soft nor too hard—perfect for specific applications like non-marking squeegees.

Excellent Sealing

DEF Rubber sheets are soft with good elasticity, conforming perfectly to working surfaces to ensure effective sealing. This is particularly important in applications such as squeegee blades for floor scrubbers, where a perfect seal ensures complete removal of dirty water.

Oil Resistance

DEF Rubber’s polyurethane non-marking rubber sheets and products offer excellent oil resistance, compensating for the shortcomings of natural rubber, allowing them to be used in oil-rich environments.

Customization Available

DEF Rubber can customize rubber sheets to meet specific requirements in terms of shape, size, thickness, color, and hardness, catering to diverse needs.

Common Applications of DEF Non-Marking Rubber Sheets

Floor Scrubber Squeegees

One of the most typical applications of DEF non-marking rubber sheets is in floor scrubber squeegees. These squeegee blades must effectively remove dirty water without damaging the floor, while also requiring excellent wear and tear resistance. DEF squeegees excel in these aspects, offering perfect cleaning and a lifespan more than three times that of ordinary squeegees.

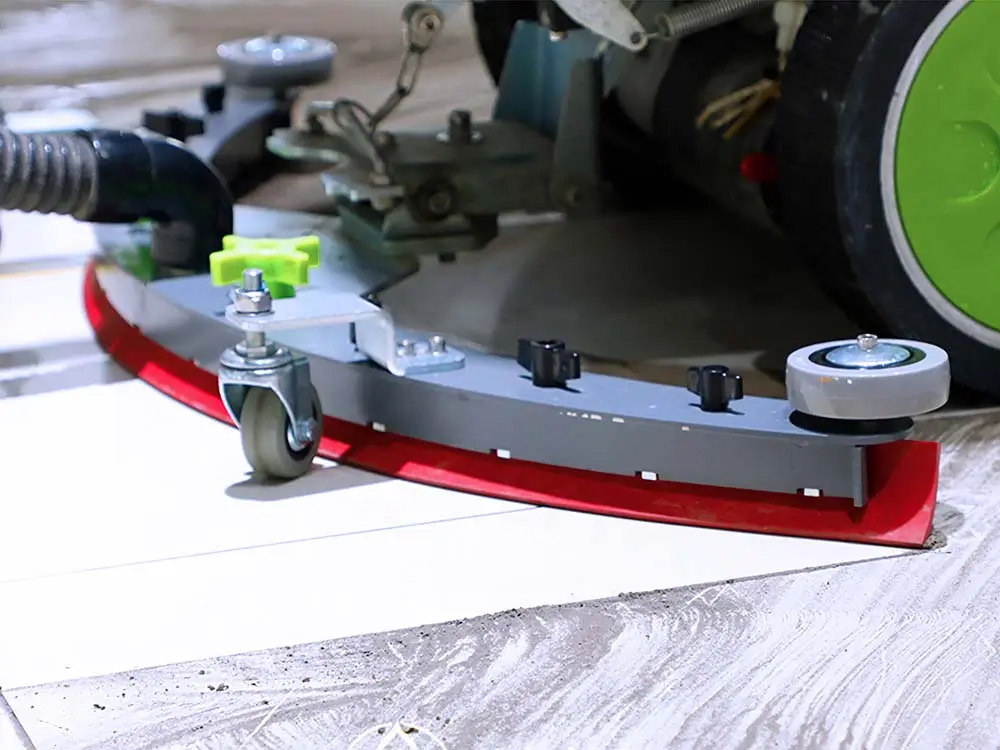

Floor Grinding Machine RUBBER Skirts

Floor grinding machines (concrete grinder) generate a lot of dust during operation. To contain the dust effectively, the rubber skirt (dust skirt) at the base of the machine must provide a tight seal while avoiding damage to the floor. Rubber skirts made from DEF rubber sheets have received excellent feedback from customers, offering great sealing performance and extended lifespan while being gentle on surfaces.

DEF non-marking rubber sheets are also widely used in other fields, including industrial, food, pharmaceutical, and sports and fitness industries. If you’re interested in non-marking rubber sheets, feel free to contact DEF Rubber.

FAQs About Non-Marking Rubber Sheets

Join DEF Rubber as a Global Distributor?

If you’re interested in high-quality rubber sheets from DEF Rubber, apply to become a global distributor or reseller. Our advantages include:

- Quality and Service: Excellent quality and free sample service allow you to make informed decisions.

- Cost-Effectiveness: By avoiding high brand premiums, DEF Rubber offers superior cost-effectiveness and profit margins compared.

- Simple Sales Model: With straightforward product models and weight-based pricing, quoting is easy.

- Few Competitors: Few manufacturers produce and sell this special high-wear natural rubber, giving you a competitive edge.