Uncured Rubber

Explore the world of Uncured Rubber with our in-depth guide. Learn about its quality, applications, and how our company sets the standard in rubber production.

What is Uncured Rubber? – Uncured rubber meaning.

Uncured Rubber refers to rubber that has not yet undergone the vulcanization process. In this state, the rubber retains high levels of plasticity and flexibility.

Before vulcanization, uncured rubber can be easily shaped and adjusted to meet the demands of various industrial applications.

Uncured rubber plays an essential role in industrial production; after being molded and processed, it undergoes vulcanization to transform into a more durable and elastic form.

Advantages of Uncured Rubber:

When discussing the benefits of uncured rubber, its exceptional plasticity and durability make it suitable for many complex industrial fields. Its main features and advantages include:

High Plasticity

Uncured rubber boasts extreme plasticity and flexibility, allowing it to be molded into various complex shapes to meet specific application needs.

Ease of Use

It’s easier to install and use, adhering firmly and durably through thermal bonding processes.

Economic Efficiency

High material utilization rate and increased durability.

Environmentally Friendly

Made from natural latex, both the production process and the products are greener and more eco-friendly.

Outstanding Physical Properties

With excellent elasticity, wear resistance, cutting resistance, and tear resistance, it’s the ideal choice for manufacturing complex and flexible durable products.

Improved Sealing

It tightly adheres to various complex shapes, providing better sealing and protection.

Customized Production

Good plasticity allows for customized production and processing according to customer needs.

Wide Range of Applications

From mining and the automotive industry to medical equipment, uncured rubber is extensively used, including for various wear-resistant hoses, chute linings, tank linings, and rubber linings for pipes.

Applications of Uncured Rubber:

Uncured rubber, known for its excellent plasticity and adaptability, plays a significant role in complex industrial fields. Its ease of molding makes it suitable for creating products of various sizes and complex shapes.

It is widely used in mining, medical, automotive, and general industries.

In the Mining Industry:

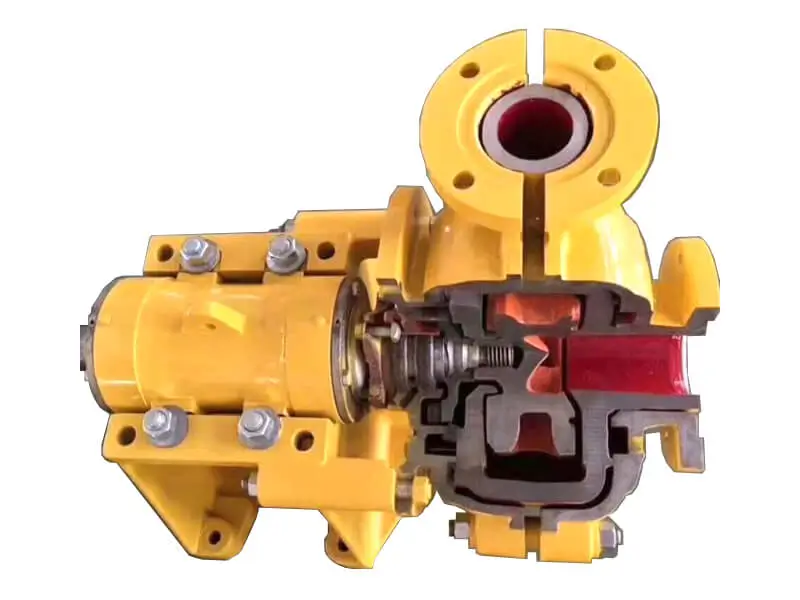

Uncured rubber effectively resists wear from mud, making it ideal for producing various mud pumps and hoses, wear-resistant rubber linings for tanks, pipes, and chutes. It is also used to make complex-shaped rubber lining parts and wear-resistant components such as mixer blades and rubber screens for drums.

In Other Industrial Sectors:

It is used to manufacture wear-resistant liners for various pipes, valves, and pumps. It is also utilized in creating complex-shaped waterproof, insulating, sealing, and wear-resistant products.

How to Choose the Right Uncured Rubber Suppliers?

When purchasing uncured rubber, consider the following factors:

Why Choose DEF Rubber?

Compared to other suppliers, DEF Rubber’s Uncured Rubber products offer the following advantages:

Let’s explore how to use this versatile material, uncured rubber, to create innovative and efficient solutions.

We will continuously innovate, grow together with our customers, and be your best partner.

Technology Sharing

Quick Q&A-About Uncured Rubber.

DEF Rubber Co.,Ltd.

Get in touch with us today!

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.