DEF Rubber Co.,Ltd.

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.

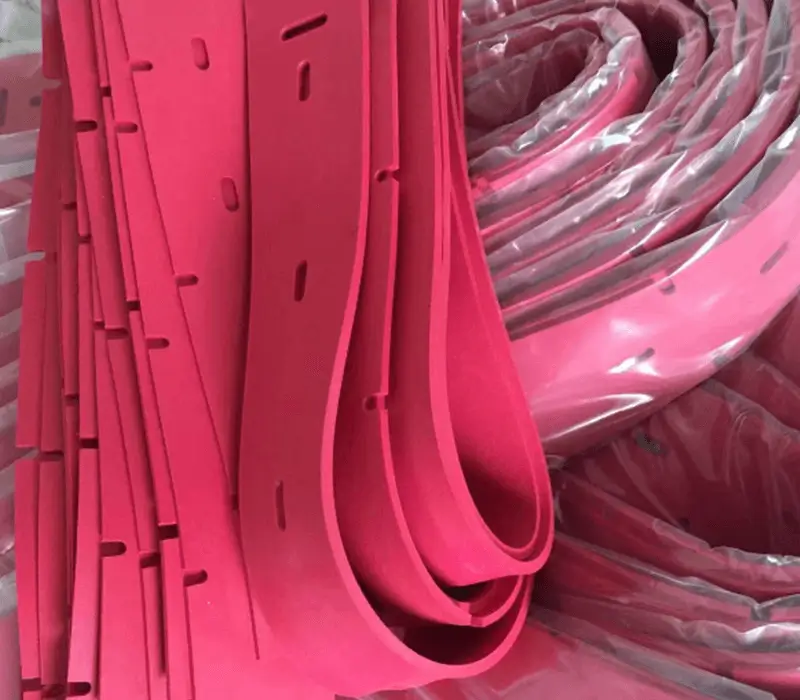

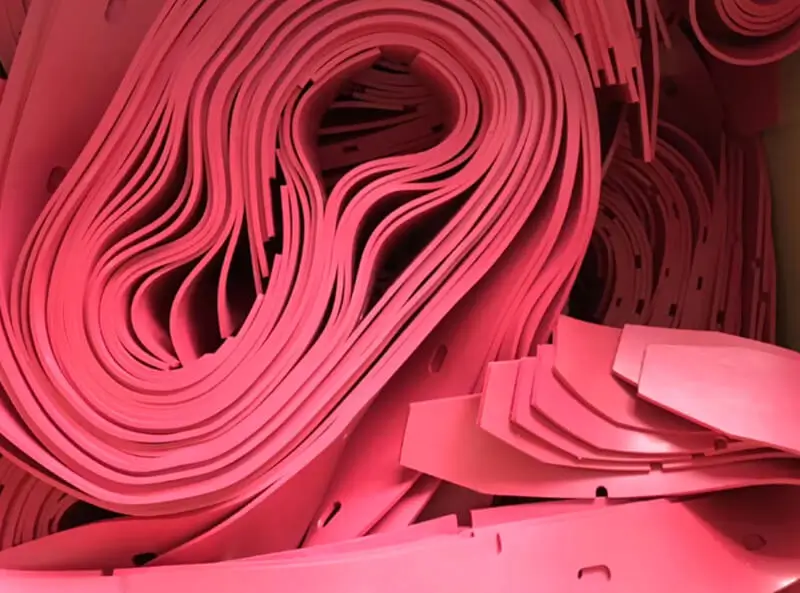

Explore the application of high-performance, wear-resistant rubber in floor grinder dust skirts. Its excellent sealing ability and durability make it the ideal material choice for dust skirts.

What is a Floor Grinder Rubber Dust Skirt?

A floor grinder rubber dust skirt, also known as a floor machine dust skirt or floor polisher dust skirt, is an annular rubber skirt structure installed at the bottom of a floor grinder. Its excellent sealing properties limit the spread of dust and debris. Typically made from wear-resistant rubber, it forms a sealed area at the bottom of the machine during operation, containing the dust within the grinding zone and preventing it from spreading into the surrounding environment.

Why Should You Install a Rubber Dust Skirt on Your Floor Grinder?

- Reduces Dust Spread: Floor grinders generate a significant amount of dust during operation. The rubber dust skirt creates a sealed space by making contact with the floor, greatly reducing the dispersion of dust. This is especially important when working indoors or in enclosed spaces.

- Improves Air Quality: By containing dust, it improves air quality, especially during prolonged grinding sessions. This helps reduce air and environmental pollution, supporting a greener, more eco-friendly workspace.

- Enhances Comfort and Safety: By lowering airborne dust concentration, it reduces workers’ exposure to harmful dust particles, increasing both the comfort and safety of the working environment. This is particularly crucial when working with toxic or hazardous materials.

- Boosts Efficiency and Extends Equipment Life: Reducing dust dispersion minimizes post-work cleanup time, improving operational efficiency and maintaining a cleaner work environment. Additionally, the machine is less likely to ingest dust, which helps extend its lifespan.

Why DEF Rubber’s Wear-Resistant Natural Rubber is the Best Choice for Floor Grinder Rubber Dust Skirts

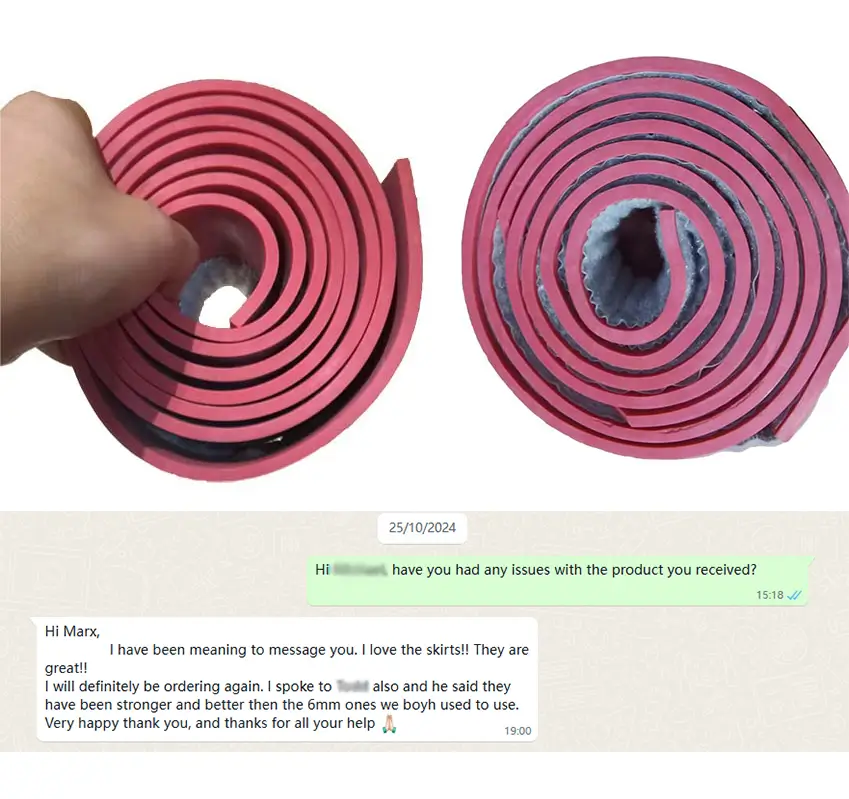

- Superior Durability: DEF Rubber uses a specialized formula and process, making its wear-resistant rubber over three times more durable than comparable products, significantly extending the lifespan of the dust skirt.

- Mark-Free Rubber Sheets: DEF’s rubber sheets typically have a Shore hardness of 36-40, offering softness, good elasticity, and excellent floor contact. They leave no marks on the surface and won’t cause any damage to the floor.

- Strong Adaptability: DEF Rubber’s materials are suitable for use on various floor types, including concrete, stone, wood, and cement floors.

- Custom Solutions: DEF Rubber offers customized dust skirts in different sizes, colors, and specifications, providing tailored OEM services to meet specific client needs.

How to Customize a Rubber Dust Skirt for Your Floor Grinder?

Different models of floor grinders require different types of rubber dust skirts. DEF Rubber can custom-make floor grinder dust skirts based on the drawings or specifications you provide. We have successfully customized dust skirts in various shapes and colors for different clients, receiving excellent feedback. The production of dust skirts often involves collaboration with various material suppliers and manufacturers. We may need to sew Velcro or nylon straps onto the rubber skirt, depending on your requirements, and DEF Rubber can accommodate these customizations.

Other Dust Skirt Products

In addition to floor grinder rubber dust skirts, DEF Rubber also offers custom services for floor buffer dust skirts, floor sander dust skirts, and other similar products.

DEF employs an ultra-high molecular weight nano-curing agent, enhancing its wear resistance significantly.

During operation, the Natural Rubber Sheet may be damaged in these areas without sufficient tear strength in the material.

Greater material resilience ensures faster restoration, maintaining high airtightness in assembly parts.

Oily environments, traditional rubber can expand and deform, so consider using Oil-Resistant Rubber Sheets.

More Information About floor grinder rubber dust skirt

You may still have many questions about floor grinder rubber dust skirt. Continue to check the FAQs about it.