DEF Rubber Co.,Ltd.

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.

High-quality wear-resistant rubber valve liners can extend service life by 2-4 times.

Using high-quality natural wear-resistant rubber liners in knife gate valves significantly reduces equipment use and maintenance costs.

What is a Knife Gate Valve?

A knife gate valve is used for fluid control, especially in handling fluids with solid particles. Its unique design features a blade-like valve plate that cuts through media to prevent clogging.

Common Issues with Knife Gate Valves:

- Sealing Problems: Poor sealing or degradation over time can cause leaks.

- Corrosion: Corrosive fluids can damage valve materials, reducing lifespan.

- High Operating Force: Requires significant force to operate, especially with high-pressure or particulate-laden fluids.

- Clogging: Despite its design, it can still clog with high concentrations of solid particles.

Why Use DEF Rubber Wear-Resistant Liners?

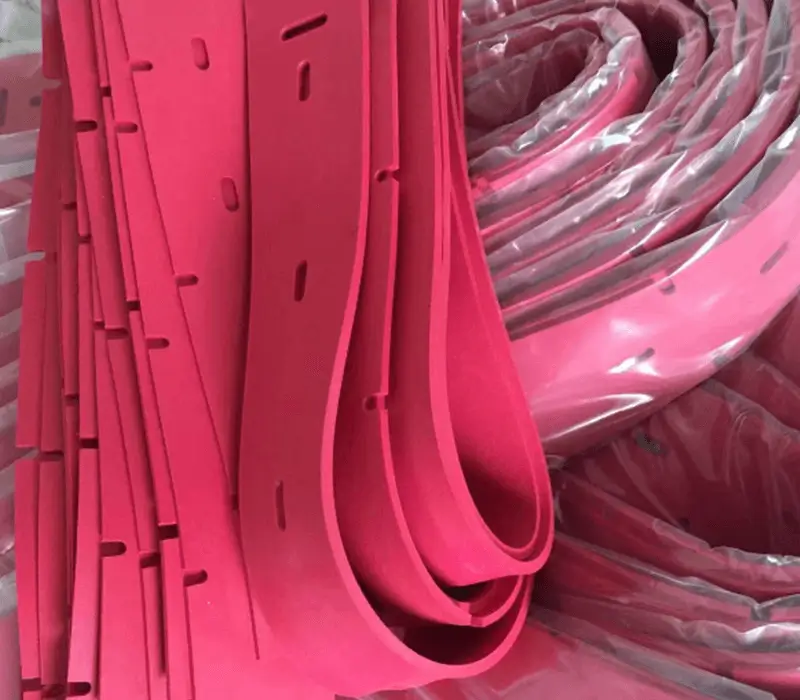

DEF Rubber liners are made from natural wear-resistant rubber, with a unique formula and over 95% natural rubber content, maintaining long-chain molecular structure for excellent wear, corrosion, cut resistance, and tensile strength. Benefits include:

- Long Lifespan: Wear index over 125%, extending life by over three times.

- Excellent Sealing: Over 80% elasticity ensures tight sealing, preventing water hammer effects.

- Non-Clogging Flow Paths: Smooth rubber surface reduces clogging risk.

Additionally, they minimize pressure loss, simplify operation and maintenance, significantly reducing overall costs.

DEF Rubber: Professional Wear-Resistant Liner Manufacturer

DEF Rubber Co., Ltd. specializes in producing and researching high-quality natural wear-resistant rubber. Their products meet international standards and are praised for replacing Lina-tex-type Rubber in mining equipment, floor scrubber squeegees, rubber target backings, and more.

They offer custom rubber sheets in various sizes and colors, supported by robust financial resources, advanced production equipment, standardized processes, and strict quality control, along with strong after-sales and technical support.

DEF employs an ultra-high molecular weight nano-curing agent, enhancing its wear resistance significantly.

During operation, the Natural Rubber Sheet may be damaged in these areas without sufficient tear strength in the material.

Greater material resilience ensures faster restoration, maintaining high airtightness in assembly parts.

Oily environments, traditional rubber can expand and deform, so consider using Oil-Resistant Rubber Sheets.

More Information About Rubber Lined Knife Gate Valve

You may still have many questions about Knife Gate Valve. Continue to check the FAQs about it.