Floor Scrubber Squeegee

The highest tensile strength.

Making it the best material for manufacturing Floor Scrubber Squeegees.

The optimal material for Floor Scrubber Squeegees.

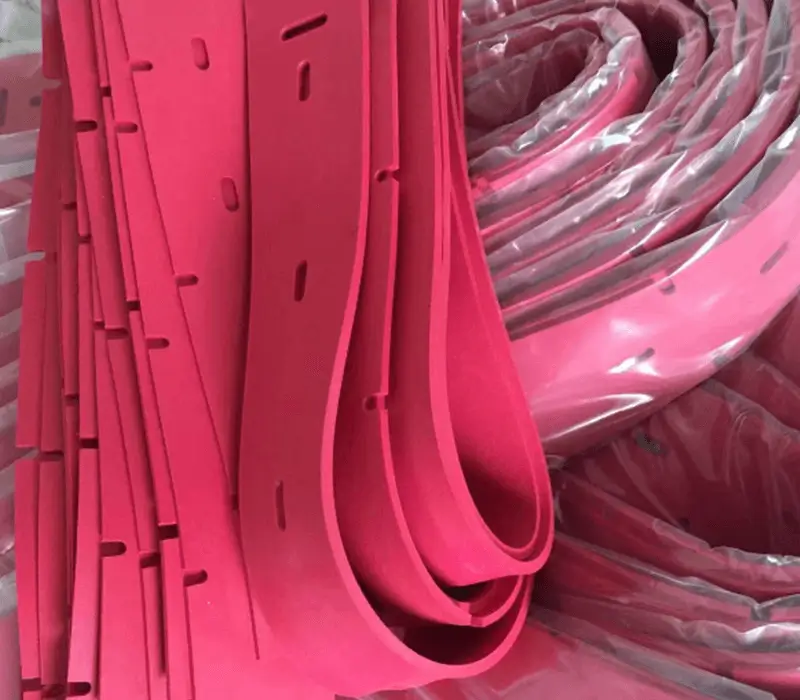

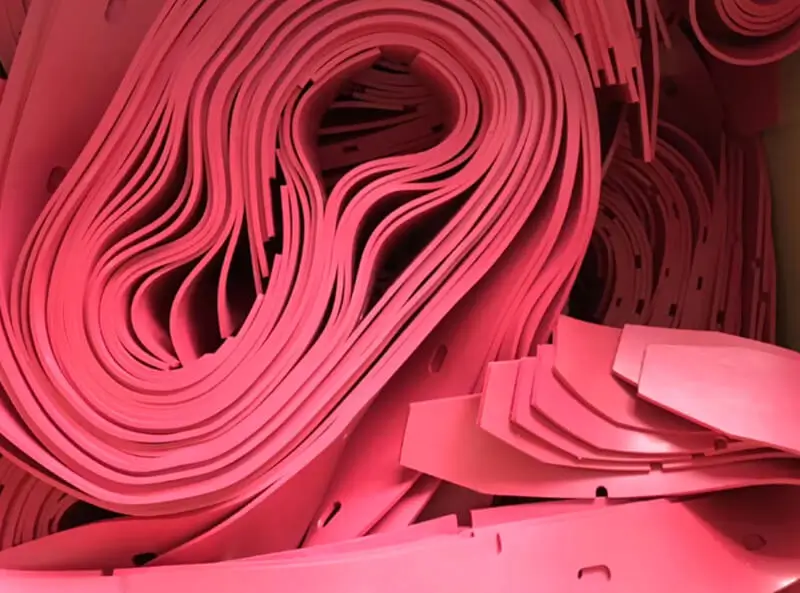

We employ a unique formula in our Squeegees, delivering exceptional wear resistance, resilience, and resistance to cutting and tearing, ensuring outstanding performance in wet abrasion conditions. Without a doubt, it stands as the optimal material for Floor Scrubber Squeegees, a fact well-supported by our satisfied customers. In addition to our standard red Wear-resistant Squeegees, we also offer Oil-resistant Squeegees for use in oil-rich environments, catering to a broader range of your needs. Furthermore, we don’t limit ourselves to Rubber Sheets; if you have specific design requirements, we can cut them to your desired shape based on your drawings.

How to Choose the Right Floor Scrubber Squeegees?

Wear-Resistance

The higher the material’s abrasion resistance, the longer the squeegee’s lifespan. We utilize an ultra-high molecular weight nano-curing agent, ensuring excellent wear resistance, especially in wet abrasion environments.

Hardness&Resilience

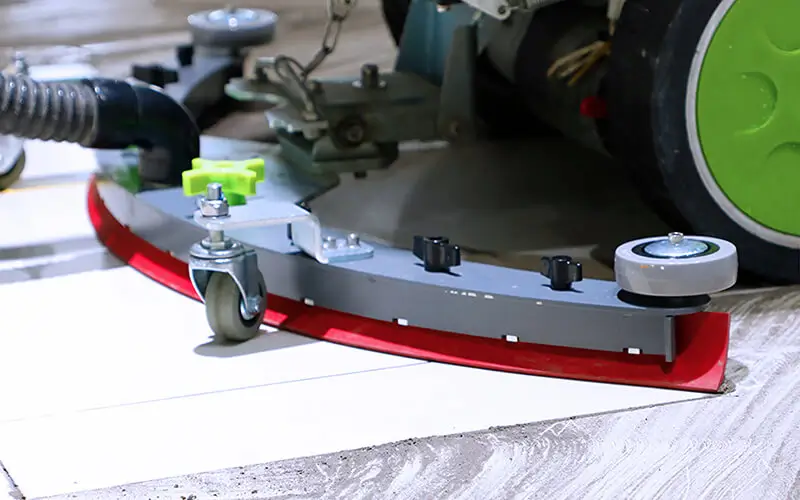

If the Squeegee Blade is too hard and lacks resilience, it may be challenging to assemble and won’t adhere well to the surface. Conversely, if it’s too soft, it can be easily drawn in by negative pressure. Therefore, a Squeegee with moderate hardness and good resilience is your best choice.

Tear-Resistance

Because we incorporate many perforations into our Squeegee Blades, if the material lacks adequate tear resistance, it can easily break at these points during operation. However, we have overcome this limitation.

Sharp Edge

Regardless of the material used for Squeegee Blades, any rough edges or other defects can prevent our Squeegee Blades from properly adhering to the floor, resulting in leaks. Therefore, sharp and tidy trimming is essential to ensuring the efficient performance of our Floor Scrubber Squeegees.

Natural Rubber Sheets and cutting services

DEF Rubber specializes in producing high-quality Natural Rubber Sheets. We recognize that Natural Rubber is an excellent environmentally friendly material due to its biodegradable nature. Its outstanding wear resistance, tear resistance, and elasticity in wet grinding conditions make it the preferred choice for producing Floor Scrubber Squeegee. DEF Rubber can customize Rubber Sheets to meet your specific requirements. If you need finished products, we also offer cutting services. We understand that precise cutting and clean edges are crucial for the quality of Squeegee Blades.

High-quality Floor Scrubber Squeegees.

We’ve improved the formula through nano macromolecular modification, achieving a perfect balance of high elasticity and wear resistance. This has significantly improved the water absorption performance and lifespan of the product.

Oil-Resistant Floor Scrubber Squeegees.

Our exclusively developed liquid rubber material boasts excellent oil and chemical resistance characteristics, making it suitable for use in even the most demanding oil-rich environments.

Economy Floor Scrubber Squeegees.

To cater to the diverse needs of our customers, we also manufacture cost-effective economy-grade squeegee blades that can likewise meet the requirements of the majority of environments.

Our sole pursuit is to deliver excellent products and serve our customers.

We will continuously innovate, grow together with our customers, and be your best partner.

Technology Sharing

Quick Q&A-About Floor Scrubber Squeegee.

The squeegees for floor scrubbers are typically made from rubber sheet materials, and their performance, durability, and ability to adapt to various cleaning environments are crucial for the cleaning effectiveness of floor scrubbers. Here are some common questions and their answers regarding “floor scrubber squeegees”:

DEF Rubber Co.,Ltd.

Get in touch with us today!

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.