What are the special requirements for squeegee blades used in food factories?

The material commonly used for auto floor scrubber squeegee blades is what?

Auto floor scrubber squeegee blades are typically made from natural or synthetic rubber. Positioned at the bottom of the scrubber, these blades make direct contact with the floor, creating a sealed area to absorb wastewater and clean the surface. The quality of these rubber blades directly impacts the cleaning effectiveness and efficiency of the scrubber. Rubber material, known for its excellent wear resistance and chemical corrosion resistance, is highly suitable for making auto floor scrubber blades, effectively cleaning various floor types.

What are the differences between squeegee products used in food factories and those used in regular environments?

We understand that food production and processing require a higher environmental standard. Compared to regular use scenarios, the possible differences for food factory applications mainly include:

- Material Safety: Food factories demand high safety standards for materials used, necessitating non-toxic materials that do not contaminate food. Often, food-grade materials are required, which also need to withstand frequent cleaning and disinfection.

- Oil and Chemical Resistance: Food processing often involves various oils and fats, creating an oil-rich environment. Additionally, various disinfectants and cleaning agents are regularly used in food processing areas, necessitating higher oil and chemical resistance in squeegee materials.

- Temperature Resistance: Food processing typically involves high-temperature sterilization or operations at lower temperatures to prevent spoilage, requiring squeegee materials with a broader range of temperature adaptability.

What material is suitable for food factory floor scrubber squeegees?

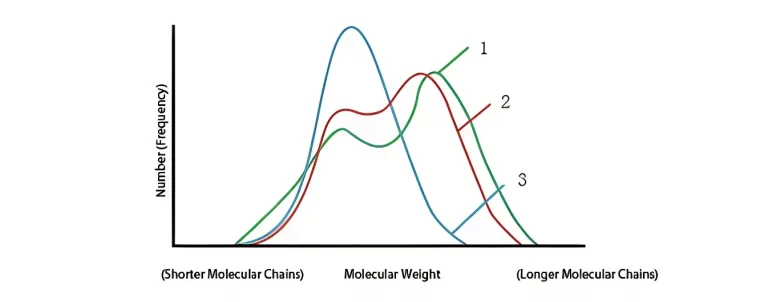

As we’ve mentioned, rubber is the most suitable material for making floor scrubber squeegees. However, different environments call for different types of rubber materials. The most commonly used material is high-quality natural wear-resistant rubber with over 95% natural rubber content. This material is suitable for most environments, known for its unmatched wear resistance, tear resistance, and sealing effectiveness, making it the best rubber material for wet scrubbing environments. Few international factories can produce this high-quality wear-resistant rubber sheet, with DEF Rubber and Lina-tex-type being among the leaders. However, this material has a drawback – it has low oil resistance. In oil-rich environments, it swells and degrades, affecting its performance. Therefore, it is not suitable for food factories. DEF Rubber recommends polyurethane rubber material for food factory floor scrubbers. Polyurethane rubber has excellent oil and corrosion resistance, resisting degradation from plant, animal, or mineral oils without significant swelling or degradation. Moreover, polyurethane rubber maintains good performance in temperatures ranging from -40°C to 80°C. Food-grade polyurethane rubber is non-toxic and does not cause secondary contamination to food. However, compared to high-quality natural wear-resistant rubber, polyurethane rubber has relatively lower wear resistance and is less durable in standard environments.

In summary, the oil-rich environment in food factories demands higher requirements for rubber materials, and ordinary natural wear-resistant rubber is not suitable. DEF Rubber’s specially developed polyurethane rubber material is particularly fit for use in food factory floor scrubbers. If you have more specific requirements for the material and performance of floor scrubber squeegee products, you can contact DEF Rubber, and we can customize squeegee products to meet your needs.