What is LX-Type Material?

Learn about the composition, variations, and manufacturers of LX-Type Material. Explore its applications in various fields.

- What Exactly is LX-Type Rubber?

- Why is LX-Type Material Unique?

- Typical Applications of LX-Type Material

What Exactly is LX-Type Material?

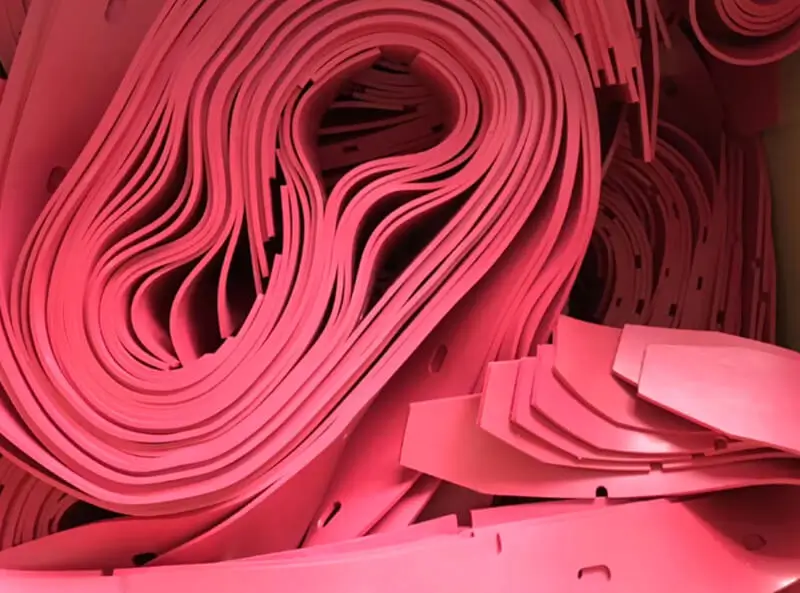

In industrial production, a highly elastic red soft sheet, commonly referred to as LX-Type Material, is widely recognized for its exceptional performance. This material is primarily composed of over 95% natural rubber, differing significantly from regular rubber sheets in terms of wear resistance, tensile strength, and lifespan. The original concept was introduced by a leading manufacturer in the industry, setting a high-performance standard for rubber products. Over the years, LX-Type Rubber has become synonymous with high-quality rubber solutions.

For more information, you can read our articles:

Why is LX-Type Material Unique?

Composition and Production Process:

LX-Type Material consists mainly of 95% natural rubber combined with small amounts of additives. Variations in manufacturing formulas result in differences in product performance across manufacturers.

DEF Rubber, a leading manufacturer in the field, produces high-wear-resistant liquid-phase natural rubber as an excellent alternative to LX-Type Material. DEF Rubber’s unique wet rubber mixing technology preserves the long-chain molecular structure of natural rubber and employs nano-particle modification to enhance the integration of additives.

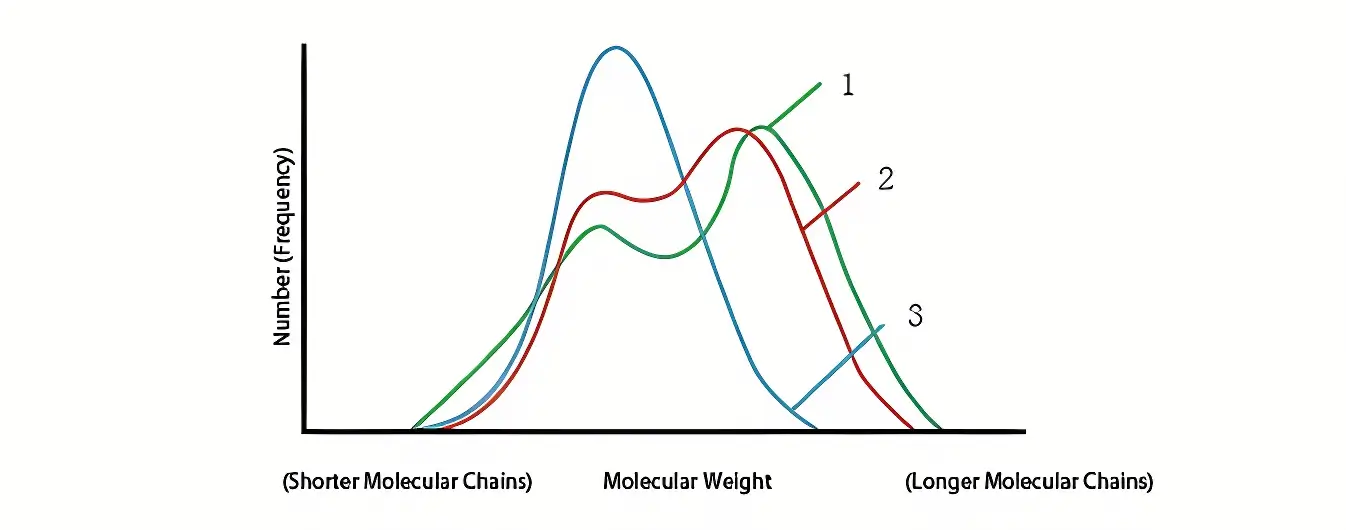

Attached Image: Molecular weight distribution comparison chart of DEF Rubber.

2. DEF Rubber perfectly preserves the molecular weight distribution structure of natural rubber

3. Ordinary compounded rubber products disrupt the long molecular chain structure of natural rubber

Features and Advantages:

Thanks to advanced wet rubber processing and unique formulas, DEF Rubber offers superior tensile strength and elasticity, making it an ideal wear-resistant material for slurry applications.

- Exceptional Physical Properties: High elasticity, strength, tear resistance, and wear resistance have been proven in practical use to protect equipment surfaces and extend lifespan.

- Energy Saving and Noise Reduction: Excellent wear resistance and elasticity protect equipment, reduce energy consumption, and lower noise levels.

- Simplified Maintenance: With a lifespan over three times that of ordinary wear-resistant rubber, maintenance frequency is greatly reduced, making upkeep easier and more convenient.

- Cost-Effectiveness: DEF Rubber combines outstanding performance with competitive pricing, eliminating the high cost often associated with premium rubber brands. If interested, please contact us.

Typical Applications of LX-Type Material

Its unique physical and chemical properties make LX-Type Material widely used in high-end applications, including mining equipment such as slurry pump linings, rubber impellers, and rubber screens, hydrocyclone liners, and other high-wear pipelines, pumps, and valves. It also finds applications in other demanding fields. Learn more about its applications:

With DEF Rubber’s cost-effective LX-Type Material, it is now a viable alternative in fields previously dominated by ordinary wear-resistant rubber. Continuous innovation and cost reduction ensure shared profits and mutual progress with customers.

Disclaimer

This article uses the term ‘LX-Type Rubber’ for clarity. We are not affiliated with, endorsed by, or authorized by any specific brand. All trademarks mentioned in this article are the property of their respective owners. This article is for informational purposes only and does not imply any partnership, sponsorship, or endorsement.