DEF Rubber Co.,Ltd.

We are glad to offer free samples to people who are interested in our products. You just need to fill a form.

Learn about the functions and materials of rubber check valves to guide your purchase.

What is a Rubber Check Valve?

A rubber check valve prevents backflow by using the fluid’s own pressure to open or close the valve. Made mainly of rubber, it offers excellent sealing and flexibility. When fluid flows in the correct direction, pressure pushes the valve open, allowing flow. When fluid reverses, pressure forces the valve shut, preventing backflow. Commonly used in wastewater systems, hydraulic projects, chemical plants, and industrial pipelines.

Advantages of Rubber Check Valves:

- Excellent Sealing: Rubber’s flexibility and elasticity ensure a tight seal when compressed.

- Corrosion Resistance: Different rubber types can handle various fluid media.

- Ease of Use: Automatically operates based on fluid pressure, requiring no manual operation.

- Low Maintenance: Simple design with minimal maintenance requirements.

- Anti-Clogging: Flexible valve design reduces the risk of clogging.

Common Materials and Performance Requirements:

Rubber check valves are made from natural rubber, neoprene, EPDM, and fluororubber.

- Natural Rubber: Ideal for water and weak acids/bases, offering excellent wear and tear resistance. DEF Rubber’s high-quality wear-resistant natural rubber lasts three times longer than regular rubber.

- Neoprene: Better oil and corrosion resistance.

- EPDM: Superior aging and ozone resistance.

- Fluororubber: Excellent high-temperature and chemical resistance.

If you want to learn more about DEF Rubber’s wear resistance, click on ‘Wear-Resistant Rubber‘ for details.

Why Choose DEF Rubber for Check Valve Materials?

- Easy to Open: High flexibility and low opening pressure ensure smooth flow.

- Superior Sealing: High elasticity ensures no reverse leakage and minimal head loss.

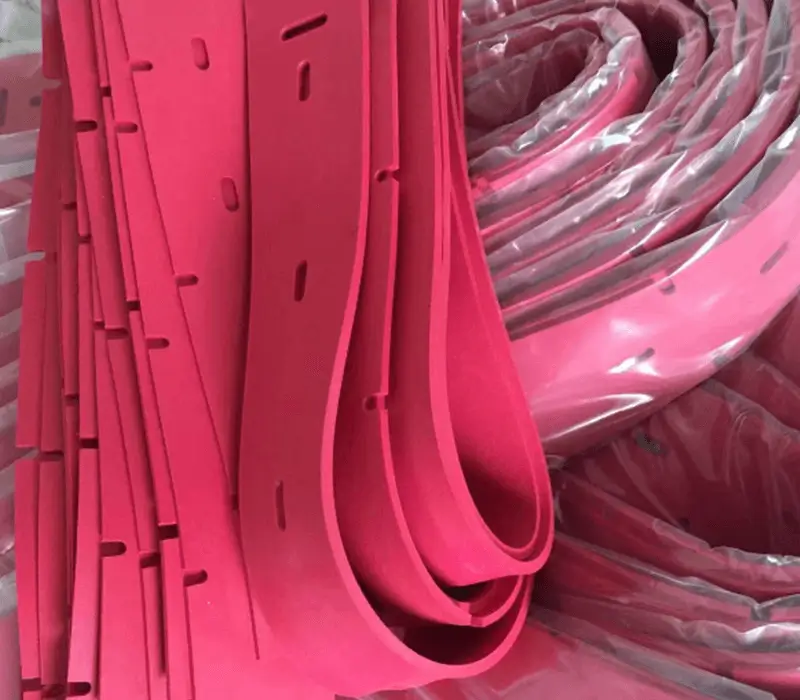

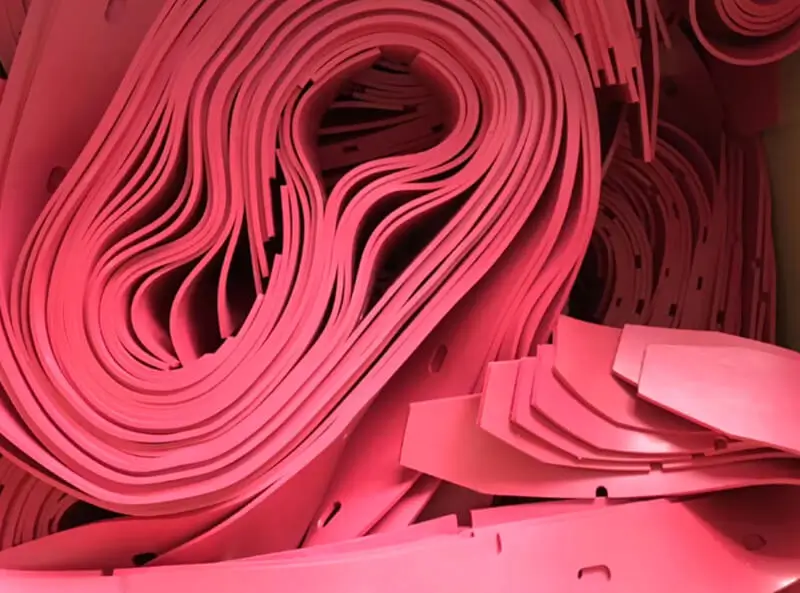

- Customizable: Shapes, sizes, and colors can be tailored to client specifications.

- Simple Installation: Can be designed for flange or clamp connections.

- Temperature Resistance: Performs well in both freezing and high-temperature conditions.

DEF employs an ultra-high molecular weight nano-curing agent, enhancing its wear resistance significantly.

During operation, the Natural Rubber Sheet may be damaged in these areas without sufficient tear strength in the material.

Greater material resilience ensures faster restoration, maintaining high airtightness in assembly parts.

Oily environments, traditional rubber can expand and deform, so consider using Oil-Resistant Rubber Sheets.

More Information About Rubber Check Valve

You may still have many questions about Rubber Check Valve. Continue to check the FAQs about it.